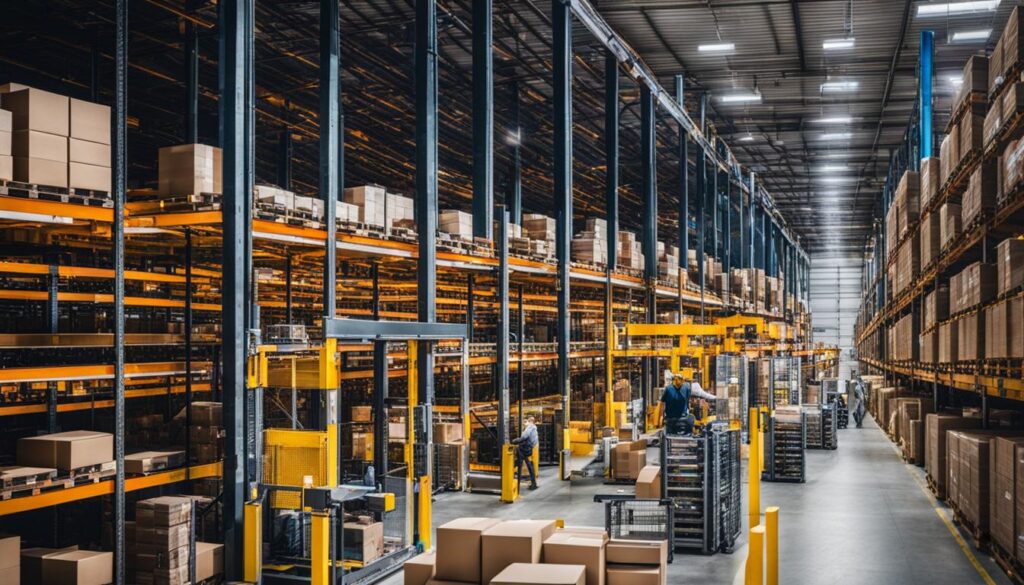

Effective logistics management is a critical element in improving the overall performance of any business. With the right warehouse management systems (WMS), companies can significantly enhance inventory control, optimize order fulfillment, and streamline supply chain management processes. By providing comprehensive, real-time insights into warehouse operations, logistics software enables businesses to stay ahead of the competition through effective utilization of resources and cost-cutting measures.

Key Takeaways:

- Warehouse management systems are essential tools for businesses seeking to optimize logistics, inventory control, and order fulfillment.

- Logistics software allows businesses to obtain real-time insights into warehouse operations for effective resource utilization.

- Streamlining supply chain management processes boosts operational efficiency and helps businesses stay ahead of the competition.

- By implementing a WMS, businesses can overcome common warehouse management challenges.

- Staying updated with emerging technologies in inventory management facilitates process optimization and enhances competitiveness.

Understanding Warehouse Management Systems

A warehouse management system is a software application designed to support and optimize warehouse operations. It helps businesses manage inventory and track products as they move through the warehouse, from receiving to shipping. Logistics software plays a crucial role in this process by providing real-time data on inventory levels, order statuses, and shipment tracking. By utilizing warehouse management systems, businesses can ensure efficient operations within their warehouses and streamline supply chain management to enhance their competitive edge.

Warehouse management systems are powerful tools for optimizing logistics and enhancing inventory management.

Fusion Inventory Management

So inventory management for an Amazon business is a huge part of business success. We have developed an easy to use warehouse management system combined inventory management all in one. Fusion Inventory Management is designed for all size warehouses and one of the only software’s on the market that management of expiration dates. Not only does it manage them, it also helps manage them on Amazon’s platform. If you sell perishable items, our inventory management if for your. If you don’t, it is still for your. We specialize in Amazon businesses and you’ll see it when you try it.

Key Features of Warehouse Management Systems

Without effective warehouse management, a business can quickly become overwhelmed with inventory and supply chain inefficiencies. Warehouse management systems (WMS) provide a comprehensive solution to these operational challenges and help businesses optimize their logistics process. In this section, we’ll take a closer look at the key features of warehouse management systems and how they enhance inventory control, supply chain management, and warehouse technology.

Inventory Control

One of the most crucial features of a WMS is its ability to manage inventory control. By tracking inventory levels in real-time and automating the fulfillment process, businesses can prevent stockouts, reduce carrying costs, and improve product availability. Additionally, a WMS can provide accurate demand forecasting and reporting, enabling managers to make informed decisions about inventory management.

Supply Chain Management

Another critical feature of WMS is its ability to streamline supply chain management. Through advanced routing and scheduling capabilities, businesses can reduce lead times and optimize delivery routes, leading to lower transportation costs and improved customer satisfaction. Furthermore, a WMS can integrate with other supply chain management systems such as enterprise resource planning (ERP) software and transportation management software (TMS), providing a comprehensive solution to supply chain management.

Warehouse Technology

Warehouse technology is an essential aspect of any effective WMS. WMS can utilize technologies such as radio-frequency identification (RFID) and barcode scanning to provide real-time tracking and updates on inventory movements. Other technologies like automated guided vehicles (AGVs) and robotic process automation (RPA) can help improve workflow efficiency and reduce errors.

Overall, the key features of warehouse management systems empower businesses to improve inventory control, streamline supply chain management, and leverage warehouse technology for enhanced efficiency.

Benefits of Implementing Warehouse Management Systems

Implementing warehouse management systems (WMS) can provide businesses with numerous benefits that can boost their efficiency and profitability. One of the most significant advantages is improved order fulfillment processes. With a WMS, businesses can track orders in real-time, from the moment they are received to the moment they are shipped. This ensures greater accuracy and efficiency, reducing the likelihood of errors and delays.

Accurate inventory tracking is also a key benefit of WMS. Companies can monitor their supplies in real-time, which helps them avoid overstocking or stocking out. This leads to better inventory control, which can prevent losses and free up capital for other investments. By improving inventory management, WMS can also streamline supply chain management and enable businesses to optimize their operations for greater efficiency.

“WMS can help businesses reduce the time and cost associated with inventory management, while improving the accuracy and efficiency of their order fulfillment processes.”

Additionally, WMS can help businesses meet their logistics and distribution goals by providing real-time visibility into their inventory and supply chain networks. This helps them make more informed decisions about shipping, storage, and transportation, which can save time and money. For businesses that handle multiple product lines, WMS can also help them manage their storage space more effectively, freeing up more room for merchandise.

Choosing the Right Warehouse Management System

Choosing the right warehouse management system (WMS) can make a significant impact on your business operations. When selecting a WMS, it’s essential to consider the specific needs of your business and the features that the software offers. One crucial factor to consider is the software’s distribution management capabilities. If your business involves managing multiple warehouses or locations, choosing a WMS that can handle distribution management can streamline your operations and enhance efficiency.

Another important factor is scalability. As your business grows, your software needs will change. Ensure the WMS you choose can adapt to your business’s evolving requirements, and offer room for expansion as your operations expand.

There are many logistics software options on the market, each with different features. By carefully assessing your business needs and taking time to research and compare your options, you’ll be better equipped to select the WMS that best fits your unique requirements and optimizes your logistics processes.

Implementing a Warehouse Management System

Successfully implementing a warehouse management system is crucial for businesses looking to optimize their logistics and inventory control processes. Below are some key steps to follow:

1. Analyze current processes

Before implementing a warehouse management system, it’s important to analyze your current processes and identify areas for improvement. This analysis should include a thorough examination of your inventory control systems, order fulfillment processes, and supply chain management practices.

2. Choose the right system

Once you’ve identified areas for improvement, it’s time to choose the right warehouse management system for your business. Consider factors such as the system’s scalability, features for inventory control and logistics software, and distribution management capabilities.

3. Integrate with existing systems

Integrating your new warehouse management system with your existing inventory control and logistics software is key to ensuring a smooth transition. This can be a complex process, so be sure to work closely with the system provider and any IT personnel involved.

4. Train your staff

Training your staff to effectively use the new system is crucial to realizing its full benefits. This training should include detailed instructions on how to use all the features of the warehouse management system relevant to inventory control and logistics software.

5. Monitor and optimize

After implementation, it’s essential to monitor the performance of your new warehouse management system and continually optimize its use. This may involve modifying existing processes based on system data analysis and identifying areas for further improvement.

Implementing a warehouse management system can be a game-changer for businesses looking to streamline their logistics and enhance their inventory control processes. By following these key steps and utilizing the system’s features deemed applicable to inventory control and logistics software, companies can realize significant improvements in efficiency and overall performance.

Best Practices for Warehouse Management System Optimization

Optimizing warehouse management systems requires careful implementation of efficient inventory management techniques and streamlined supply chain processes. Here are some best practices to ensure the optimal functioning of warehouse management systems:

Track Inventory Accurately Using Technology

Utilize warehouse technology such as barcode scanners and radio-frequency identification (RFID) to track inventory in real-time. This ensures accurate recording of inventory, minimizes discrepancies, and helps in avoiding stockouts or overstocking.

Implement Effective Orders Management

Automate order processing to reduce manual input errors, lower processing time, and improve overall order accuracy. This includes the use of electronic data interchange (EDI), routing guides, and other order fulfillment technologies.

Improve Supply Chain Visibility

Establish better communication channels with suppliers, customers, and logistics providers. This helps to improve supply chain visibility and increase transparency, reducing inefficiencies and cycle-time in the supply chain.

Optimize Warehouse Layout and Design

The warehouse layout should be optimized to allow quick and easy access to frequently accessed items, materials, and equipment. This prevents delays, reduces the travel time for staff, and minimizes errors in processing orders efficiently.

Ensure Staff Training and Engagement

Invest in training and engaging warehouse staff to ensure seamless integration and utilization of new technologies. This creates a positive work environment, encourages employee ownership, and increases efficiency.

Implementing these best practices can help businesses optimize their warehouse management systems, streamline their supply chains, and improve inventory control.

Overcoming Challenges in Warehouse Management

Implementing a warehouse management system can be a significant shift for a business. However, with any technological adoption, it comes with its own set of challenges. Here are some common challenges and potential solutions:

1. Resistance to Change

Resistance to change is common among employees when implementing new technologies. It can be due to an apprehension of the unknown or fear of job losses. It’s essential to communicate the benefits of the warehouse management system and involve employees in the transition process.

2. Inaccurate Data

Inaccurate data can be a result of poor data entry or system integration issues. Regular training of staff to ensure they are aware of their responsibilities and the correct usage of the system can help mitigate this problem. It’s also essential to identify system integration issues and implement appropriate corrective actions.

3. Implementation Costs

The cost of implementing a warehouse management system can vary depending on the size and complexity of the organization. In some cases, utilizing a cloud-based warehouse management system can reduce implementation costs. To stay within budget, it’s necessary to analyze implementation costs thoroughly before selecting a warehouse management system.

4. Integration with Other Business Systems

Having a warehouse management system that seamlessly integrates with other essential business systems is crucial. It allows for more efficient workflows and more accurate data management. It’s essential to identify integration requirements and conduct thorough testing to ensure all systems work correctly together.

5. Maintenance and Support

Like any technology system, a warehouse management system requires maintenance and support. Having a reliable vendor that offers prompt support and regular system updates can help reduce downtime and ensure optimal system functionality.

| Challenge | Solution |

|---|---|

| Resistance to Change | Communicate the benefits of the system and involve employees in the transition process |

| Inaccurate Data | Regular training of staff and identifying system integration issues that require corrective action |

| Implementation Costs | Thoroughly analyze implementation costs before selecting a system and consider cloud-based options |

| Integration with Other Business Systems | Identify integration requirements and conduct thorough testing to ensure all systems work together correctly |

| Maintenance and Support | Select a reliable vendor that offers prompt support and regular system updates |

By identifying and addressing these common challenges, businesses can mitigate risks and maximize the benefits of warehouse management systems and logistics software in enhancing supply chain management.

Trends in Warehouse Management Systems

The world of warehouse management is constantly evolving, with new technologies and software emerging to enhance operations and streamline processes. Keeping up with these trends and advancements can give businesses a competitive advantage and help them stay ahead of the game. Here are some of the latest trends in warehouse management systems:

1. Greater Emphasis on Inventory Accuracy

One of the key trends in warehouse management systems is a greater emphasis on inventory accuracy. With the rise of e-commerce and consumer demand for fast, accurate order fulfillment, it’s more important than ever to have up-to-date and reliable inventory data. Modern warehouse management systems are designed to provide real-time inventory tracking and visibility, allowing businesses to improve accuracy and efficiency.

2. Integration With Other Technologies

Another trend in warehouse management systems is the integration with other technologies, such as robotics and artificial intelligence. This integration can help businesses automate certain processes and tasks, such as picking and packing, leading to greater efficiency and cost savings.

3. Cloud-Based Solutions

Cloud-based warehouse management systems are becoming increasingly popular, offering businesses flexibility and scalability. With cloud-based software, businesses can easily access their data from anywhere, increase capacity as needed, and benefit from automatic updates to the software.

“As technology continues to evolve and impact the world of logistics, businesses that stay current and embrace innovation will be the ones that are most successful.”

4. Mobile Access

With the rise of mobile devices, many warehouse management systems now offer mobile access. This allows employees to access data and perform tasks from their phones or tablets, improving flexibility and efficiency.

5. Predictive Analytics

Predictive analytics is another emerging trend in warehouse management systems. By analyzing historical data and patterns, these systems can help businesses make more accurate forecasts and predictions, allowing them to better anticipate customer demand and adjust inventory levels accordingly.

Staying up-to-date with the latest trends in warehouse management systems is key to optimizing logistics, enhancing inventory management, and improving overall efficiency. By embracing innovation and leveraging new technologies, businesses can gain a competitive edge in today’s fast-paced and ever-changing business landscape.

Warehouse Management Systems Recap

In conclusion, warehouse management systems play a crucial role in optimizing logistics for businesses of all sizes. By effectively managing inventory control, order fulfillment, and supply chain management, these systems enhance efficiency, reduce costs, and improve customer satisfaction.

Understanding the key features of warehouse management systems is essential to selecting the right software that meets your business needs. Implementing the software requires careful planning and consideration, including integrating it with existing inventory control systems and training staff members to utilize its features effectively.

By following best practices for warehouse management system optimization, businesses can take full advantage of the software’s capabilities. This includes effective inventory management techniques and strategies for streamlining supply chain processes.

While there may be challenges in implementing and utilizing warehouse management systems, staying updated with the latest trends can help businesses stay ahead of the curve. Emerging technologies such as warehouse robotics and artificial intelligence are revolutionizing the field of inventory management, offering new possibilities for businesses to enhance their operations.

In summary, investing in a warehouse management system can provide significant benefits for businesses seeking to optimize their logistics operations. By choosing the right software, implementing it effectively, and staying abreast of the latest trends, businesses can realize their full potential and achieve long-term success.

Learn More About Amazon Inventory Management

FAQ

What is a warehouse management system?

A warehouse management system (WMS) is a software solution that helps businesses manage and control their warehouse operations. It automates tasks such as inventory management, picking and packing, order fulfillment, and supply chain optimization.

How does a warehouse management system work?

A warehouse management system utilizes advanced technology, such as barcode scanning and RFID, to track inventory in real-time. It enables businesses to efficiently receive, store, and ship goods, optimizing warehouse operations and improving overall supply chain management.

What are the key features of a warehouse management system?

A warehouse management system provides a range of features to enhance inventory control, supply chain management, and warehouse technology. Some key features include inventory tracking, automated order fulfillment, demand forecasting, labor management, and integration with other business systems.

What are the benefits of implementing a warehouse management system?

Implementing a warehouse management system can lead to numerous benefits for businesses. It improves order fulfillment accuracy, reduces inventory holding costs, enhances customer service, optimizes warehouse space utilization, and enables real-time visibility into inventory levels and supply chain processes.

How do I choose the right warehouse management system for my business?

When selecting a warehouse management system, consider factors such as your specific inventory control needs, the scalability and flexibility of the software, integration capabilities with existing systems, the ease of use for your staff, and the level of support provided by the vendor.

What are the steps involved in implementing a warehouse management system?

Implementing a warehouse management system involves various steps, including assessing your current processes, selecting the appropriate software, planning the implementation timeline, configuring and testing the system, training employees, and continuously monitoring and optimizing its performance.

What are some best practices for optimizing a warehouse management system?

To optimize a warehouse management system, businesses should focus on effective inventory management techniques, such as implementing cycle counting and ABC classification. Streamlining supply chain processes through real-time data analysis, integrating WMS with other systems, and regularly evaluating and refining processes are also key best practices.

What are the common challenges businesses face in warehouse management?

Some common challenges include inventory inaccuracies, inefficient picking and packing processes, lack of visibility into inventory levels, poor utilization of warehouse space, and managing peak season demand. These challenges can be overcome by implementing a robust warehouse management system and adopting industry best practices.

What are the latest trends in warehouse management systems?

The latest trends in warehouse management systems include the adoption of cloud-based solutions, the integration of artificial intelligence and machine learning for predictive analytics, the use of robotics and automation for improved efficiency, and the implementation of voice-based picking technologies for hands-free operations.